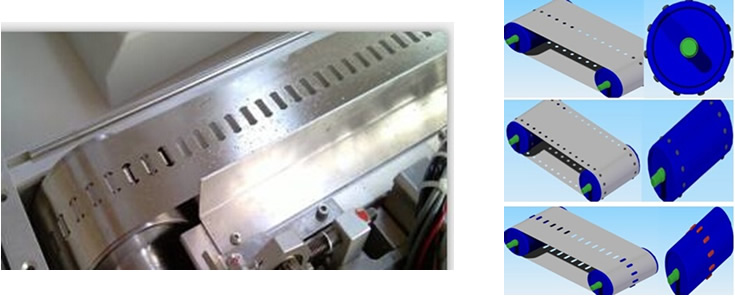

〓 Synchronous belt

The synchronous belt provided by NAUT is mainly made of special customized stainless steel belt and carbon steel belt. The holes used for positioning can be divided into single row and double row. The positioning holes are mostly round and long waist shaped. The synchronous metal belt is used for multi-type accurate conveying and positioning conveying device, which can highlight the accuracy and repeatability of the steel belt.

The advantages and characteristics of using metal as a kind of synchronous drive are incomparable to the general traditional synchronous belt. It combines the advantages and characteristics of special metal to meet the needs of more industrial environment

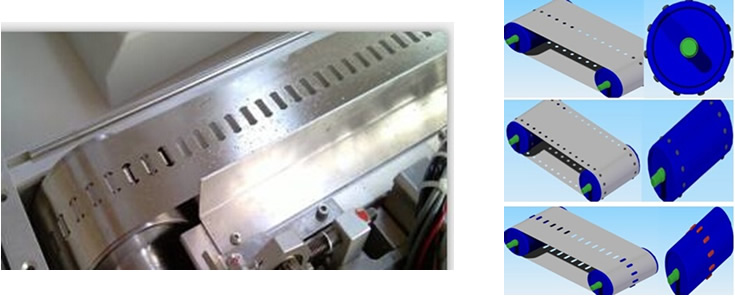

〓 Synchronous wheel

The material of synchronous wheel is determined according to different working environment and requirements. The commonly used materials are stainless steel, aluminum and wear-resistant non-metallic materials. The pulley is mostly cylindrical and I-shaped. There are some regular convex teeth or grooves on the synchronous wheel, and their shapes are mostly semicircular and long waist.

Stainless Steel:Good wear resistance, good corrosion resistance, high mechanical strength, it is the most ideal choice, the only disadvantage is the high cost.

Carbon Steel :Wear resistant, easy to rust, must do antirust treatment.

Aluminium: It is light and won't rust. It needs hard chromium plating to improve the wear resistance of the surface.

Non metallic materials:The material with certain wear resistance and high density can be used as pulley

NAUT Engineer's suggestion:

When selecting the NAUT steel belt, it is better to use the NAUT synchronous wheel, so as to avoid that the steel belt and the user designed pulley do not fit well, resulting in the failure of clamping, abnormal noise and poor operation accuracy during operation.

〓 Steel belt accessories

With the steel belt as the carrier, various components and devices can be installed on the steel belt to meet the more functional requirements. At present, in the automatic packaging production line and continuous assembly production line of medicine, food and electronic components, various forms of accessories are loaded on the steel belt, some for gear filling, and some for positioning assembly. The installation of all components must meet the bending operation conditions and anti tension limit of the steel belt.

The steel belt can not only run independently, but also be used in combination (parallel and interweaved) to meet its requirements.

Application:

Application:

● Textile industry

● Parts transfer (screws, caps, electronics, etc.)

● Robotics

● Printing, reading and writing head device

● Continuous high speed packaging system

● X-Y direction movement

● Traction frame drive

● Timing positioning clamp and assembly

● Graduation

Steel Belt Characters

Steel Belt Characters

〉High strength: The steel belt has no flexibility and will not be easily stretched. The surface is hard and the tensile strength is also very high.

〉Long usage time: It can be used in extreme temperature and harsh working environment. Each type of steel belt has its own characteristics.

〉Smooth operation: When the steel belt is running, there will be no string jumping, so as to achieve accurate transmission, at the same time, the running noise is very small.

〉Excellent conductivity: It can transmit energy in the form of heat, cold and electric current.

〉Cleaning and hygiene: Compared with other conveyor belts, it will not produce plasticizer, particles, sanitary dead angle, harmful substances and dust.