1.点击下面按钮复制微信号

点击复制微信号

上海罗特钢带系统股份有限公司

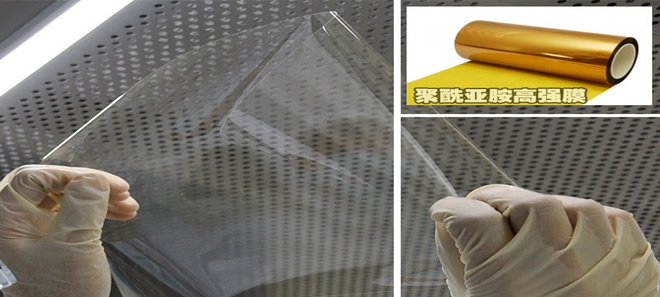

Tape casting polishing steel belt is suitable for the special requirements of film industry for steel belt surface. NAUT can produce steel belt according to customers' requirements, such as surface roughness, working performance, working environment, etc. The surface of NAUT polished steel belt has high smoothness.

|

Polish Belt type

|

Surface roughness range Unit: µm |

Quality requirement |

Thickness error range (Weld polishing area) |

|

NAUT-PG-01 |

Ra:0.01 -0.020 |

No pinhole, particle, grinding head, . |

≤0.015mm |

|

NAUT-PG-02 |

Ra:0.03 -0.035 |

≤0.02mm |

|

|

NAUT-PG-03 |

Ra:0.05 -0.08 |

No pinhole, particle |

≤0.02mm |

Characteristics of NAUTcasting polished steel belt:

◇ Ultra high tensile strength, ultra-high fatigue strength and high hardness

◇ Good corrosion resistance and wear resistance

◇ Extremely hard surface is not easy to produce scratches and pinholes

◇ High standard flatness and straightness

◇ The surface roughness and flatness of the base metal and weld joint area of steel belt are completely consistent

◇ High finish and fineness make the film easier to peel off

◇ The production process of damage, scratches and other phenomena can be repaired

Typical applications of tape casting technology are as follows:

Typical applications of tape casting technology are as follows:

◆ LCD polarizing film(TAC)

◆ LCD polarizing film(PVA)

◆ Flexible circuit board(PI)

◆ Electrical insulating tape(PI)

◆ Ceramic capacitor(MLCC)

◆ Various uses and packaging(PVA、PP)

NAUT polishing equipment:

Our polishing steel belts are all from Japan. We have imported the most advanced polishing equipment from Europe, and have the best technical resources and practical experience in the world. In the production process of polished steel belt, Electro-Slag-Remelting is used to strictly control the impurity content to meet the requirements of extremely high quality. Advanced vertical and horizontal two-way continuous polishing and grinding make the products reach the final super mirror quality.

After sale service teams

After sale service teams

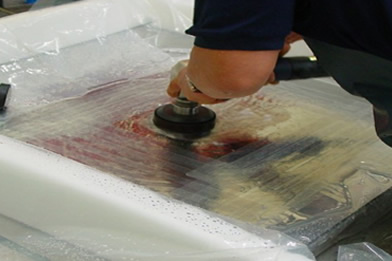

the customer's steel belt cracked, and NAUT's after-sales service engineer rushed to work until 2 o'clock in the night to complete the interpolation welding work with high quality. Ensure the normal operation of the equipment, avoid the loss of production downtime.

the engineer repairs the damaged steel belt on site, and uses sponge and abrasive tape to protect the undamaged surface in multiple layers, so as to avoid secondary injury

the engineer repairs the damaged steel belt on site, and uses sponge and abrasive tape to protect the undamaged surface in multiple layers, so as to avoid secondary injury